-40%

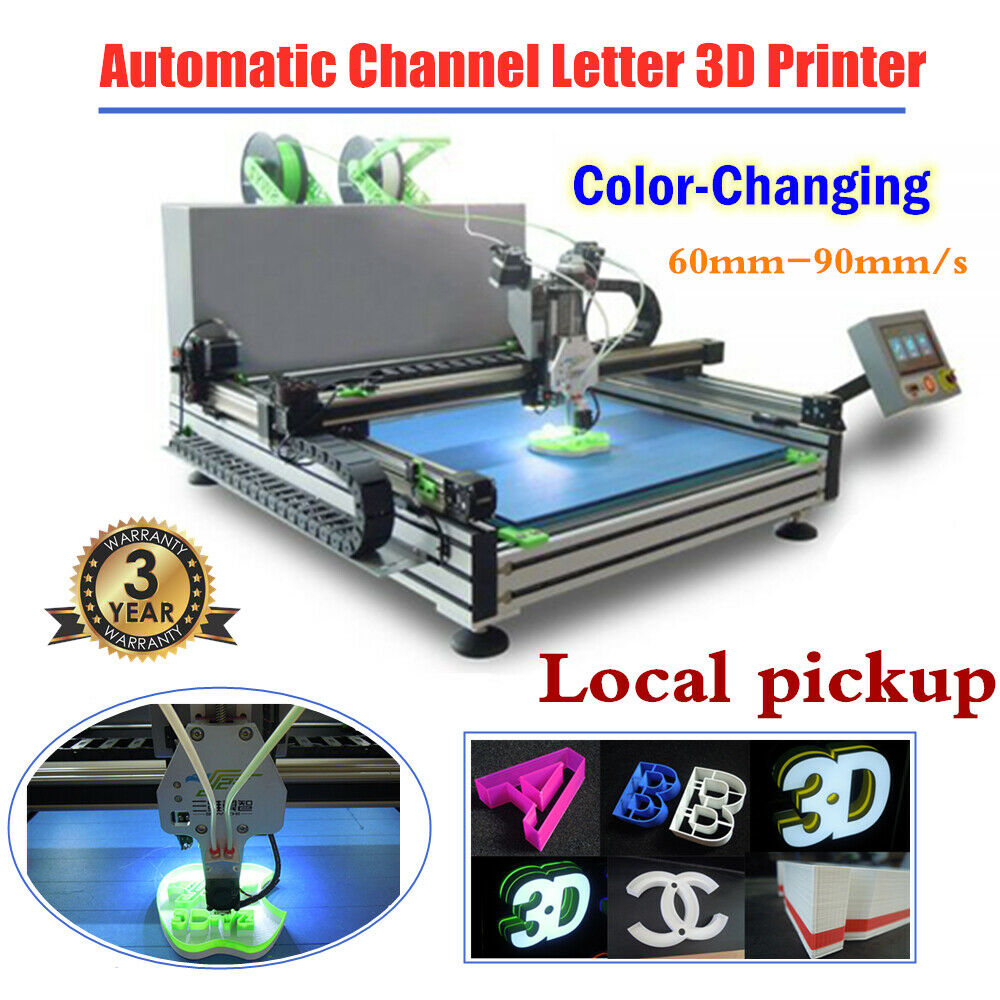

Pickup - Channel Letter 3D Printer Industrial Auto Color-Changing Shell Molding

$ 1724.02

- Description

- Size Guide

Description

US Stock, 110V Industrial Automatic Color-Changing Shell Channel Letter 3D PrinterStock in California

Local pickup price, shipment need extra fee cost

Quality Guaranteed, Professional Seller!

More Details Please Feel Free Contact us

Software Highlights:

1. Automatic color changing without modeling.

2. Software is more efficient and easy to learn.

3. S

upport wentai and CDR direct 2D to 3D, and preview files.

4. Choose any color change, print the back support, steps, the grid.

5. Offline work does not need the aid of network to be faster and more stable

3D printing is a kind of technique which using a digital technology material printer. Often used in mold manufacturing,industrial design and other fields to make models,and then gradually used in the direct manufacturing of some products. There are already parts printed using this technology.Our Industrial automatic color-changing shell 3D printer mainly used for making advertisement Channel Letter.

Machine Type and Technical Specification

Model

3DP-DWZY-640

Structure Size

Working Size

64cm(L) x 64cm(W) x 8cm(H) (25" x 25" x 3")

Packaging Size

44.5" x 44.5" x 27.5" (113 x 113 x 70 cm)

Net/Packaging Weight

165 lb / 297 lb (75kg / 135 kg)

Power Supply

Supply Voltage

110V / 220V, 50-60Hz, 5.4-2.2A, 450W

Power Supply Requirement

50-60Hz, 5.4-2.2A, 450W

Forming Parameters

Number of Forming Head

Single nozzle one (2 colors)

Size of Forms Head (Optional Matching)

0.4 mm / 0.5mm / 0.6mm / 0.8mm

Layer Resolution Ratio

100um

Positional Accuracy

Bending Torque ≤ 0.03/300mm

Straightness ≤ 0.03/300mm

Forming Material

PLA, PMMA, PVC

Material Size

1.75mm

Speed

60mm-90mm/s

Software

Software

3D Yizhi 1.4.7

Support System

Windows (7+)

Type of Support Documents

STL, CDR, ARTCUT

Human-computer Interface

Large Screen

7 inch full color screen: 6.5"x3.7" (16.5cm x 9.3cm)

Introduction of Machine Highlights:

1. Swyz-640 3D industrial grade printer is atmospheric in appearance and sturdy, with printing table: 23.6" x 23.6"x 3" (60 x 60 x 8 cm).

2. Our complete machine driving motor module drives all the motors of the printer and works for 48 hours continuously do not burn, printing life up to five years. compare printers on the market with only two drives Xy axis. Other motor driven by the motherboard, printing work 12 hours will be hot, print instability fixed, whole machine works about two years.

3. The printing platform is leveled by four micrometers, which need not be adjusted again once.

4. The printing software is very simple, 2D to 3D, and the mini word is generated automatically without 3D drawing, and the steps are generated automatically into play, easy to install the floor panel.

5. Color changing function: 0.5. Contrast the color change on the market to return to the start play. It's a waste of time.

6. Nano-coating glue independently developed by the company, which can be sprayed for repeated use, free from pressure, no edge warping, no glue leakage, and low scrap rate,after the printing is completed, the adhesive is directly poured and solidified.

7. The largest seven-inch display screen in the market. During the printing process, the temperature of the sprinkler head can be adjusted, the temperature of the hot bed, and the printing Speed.

8. During the printing process, the power is cut off and the memory storage function is available. After restoration, the printing can be continued, and there is a print Finish printing will automatically power off the function, such as the whole board printing takes 7 or 8 hours. But after work turn this on.

Detail:

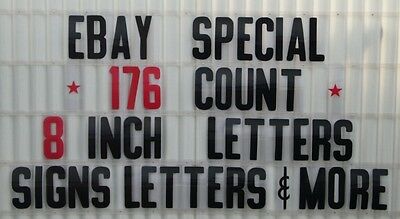

Application:

Factory:

Package: